A Taxonomy of Synthetic Turf Patent Drawings

Besler & Sons

A hard divide between concrete and synthetic turf on a sidewalk on 11th Street in the South Park neighborhood of Downtown Los Angeles. (Photograph by Ian Besler)

As the drought in Southern California carries on in its fourth punishing year, depleting groundwater reserves and demanding large scale restrictions on usage, Californians are regularly forced to confront and appraise the more unsustainable aspects of contemporary American life. For some residents, it may mean washing their vehicles less frequently, or not filling the swimmingly pool this summer.

For others, it might mean swapping their natural lawn for a simulated version. As The New York Times and Los Angeles Times have recently attested, the demand for artificial turf (commonly referred to by the brand name AstroTurf) is on the rise. While some proponents celebrate natural grass removal as a meaningful step in water use reduction, others point out that synthetic coverings reduce the viability of lawns as ecological habitats, and that producing the material is itself a resource intensive manufacturing process.

In either case, the debate provides an opportunity to examine technology, engineering, and manufacturing, and the important role that they play in how we experience the designed environments around us—from the millions of square feet of ubiquitous lawns that stretch across the country, down to the representation of the ideal blade of grass.

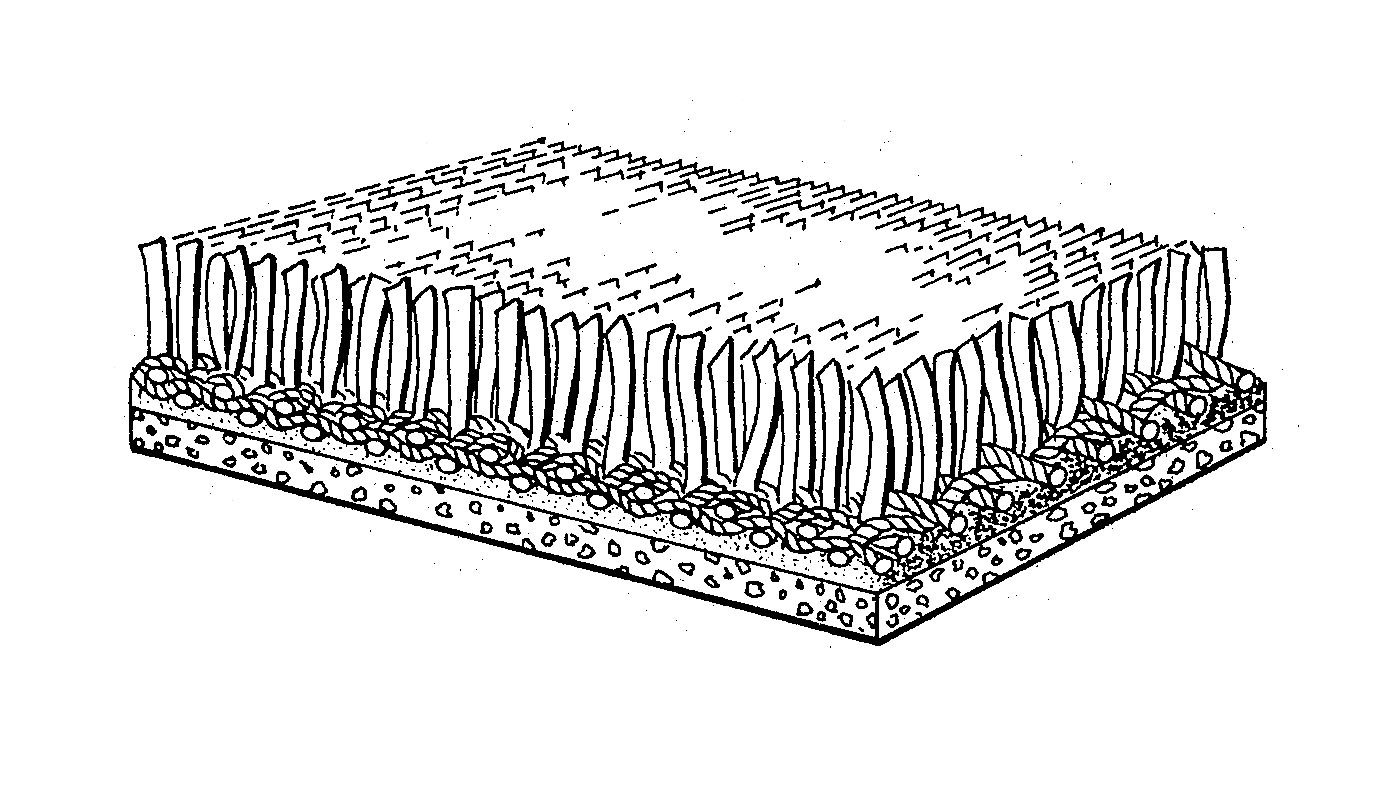

The carpet-like uniformity and unnaturally simulated quality of the original AstroTurf (initially marketed as ChemGrass) patent drawing seems to come through in its obstinate refusal to fit neatly into any one category: Is it a carpet? Or is it a scrub brush? (U.S. Patent No. 3,332,828, “Monofilament Ribbon Pile Product,” James M. Faria & Robert T. Wright, issued July 25th, 1967)

Material Performance and Convincing Synthetics

Early versions of artificial grass were available prior to the development of AstroTurf by chemists at Monsanto in the mid-1960s. The first patent filing for the ubiquitous name brand product notes that “… attempts to make artificial grasses have been made during the past several years,” but asserts that most were only intended as decorative covering. AstroTurf was the first product to make a claim for an effect beyond just the cosmetic. Research and development in synthetic polymers and stitching techniques made for a surface that could withstand heavy athletic use and outdoor installation, and promised performance characteristics “comparable with those possessed by natural turf.”

To a certain extent, the development of artificial turf mirrors many facets of American culture in the 20th century. Perusing the database of the U.S. Patent and Trademark Office for the product reveals as much. Through the late 60s and 70s, when synthetic turf was just becoming commercially viable, technological specifications often focused on the wants and needs of middle-class American suburbanites.

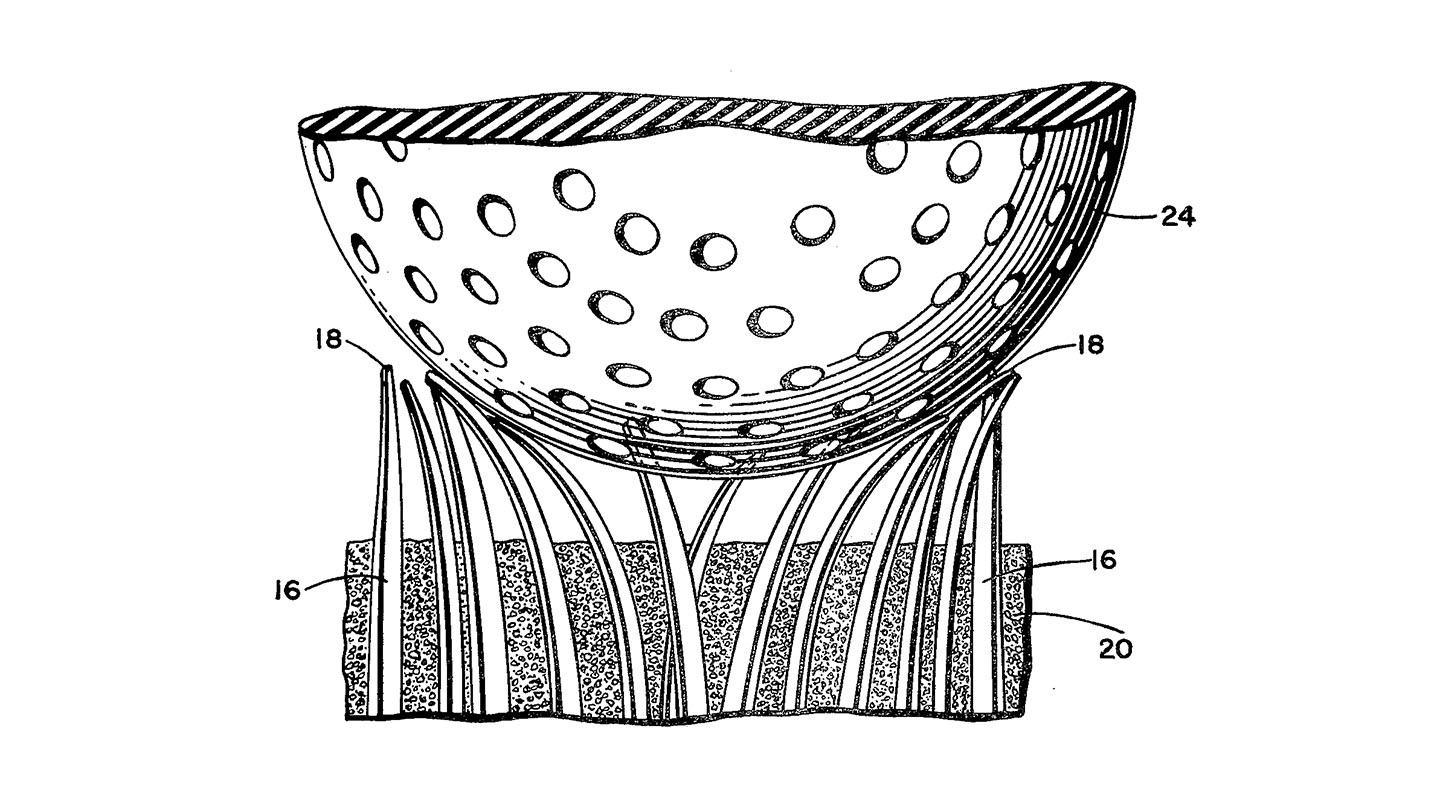

A golf ball is dramatically dissected in the pursuit of the perfect playing surface. “Thus,” writes the inventor, “the ball will behave as it does on grass.” He then goes on to assert that characteristics of his artificial surface make it equal or superior to natural grass. (U.S. Patent No. 3,995,079, “Artificial Turf-Like Product,” Frederick T. Haas, Jr., issued November 30th, 1976)

Perhaps no other recreational activity in America has been so closely associated with middle-class aspirations and professional ambition than the sport of golf. And because of the comparatively small size of the ball in play, the technical challenge of engineering the perfectly performing span of simulated grass was of significant consequence to the gameplay. The patent filings for artificial turf reveal the focused attention that inventors and engineers were willing to devote to every aspect of the product’s performance.

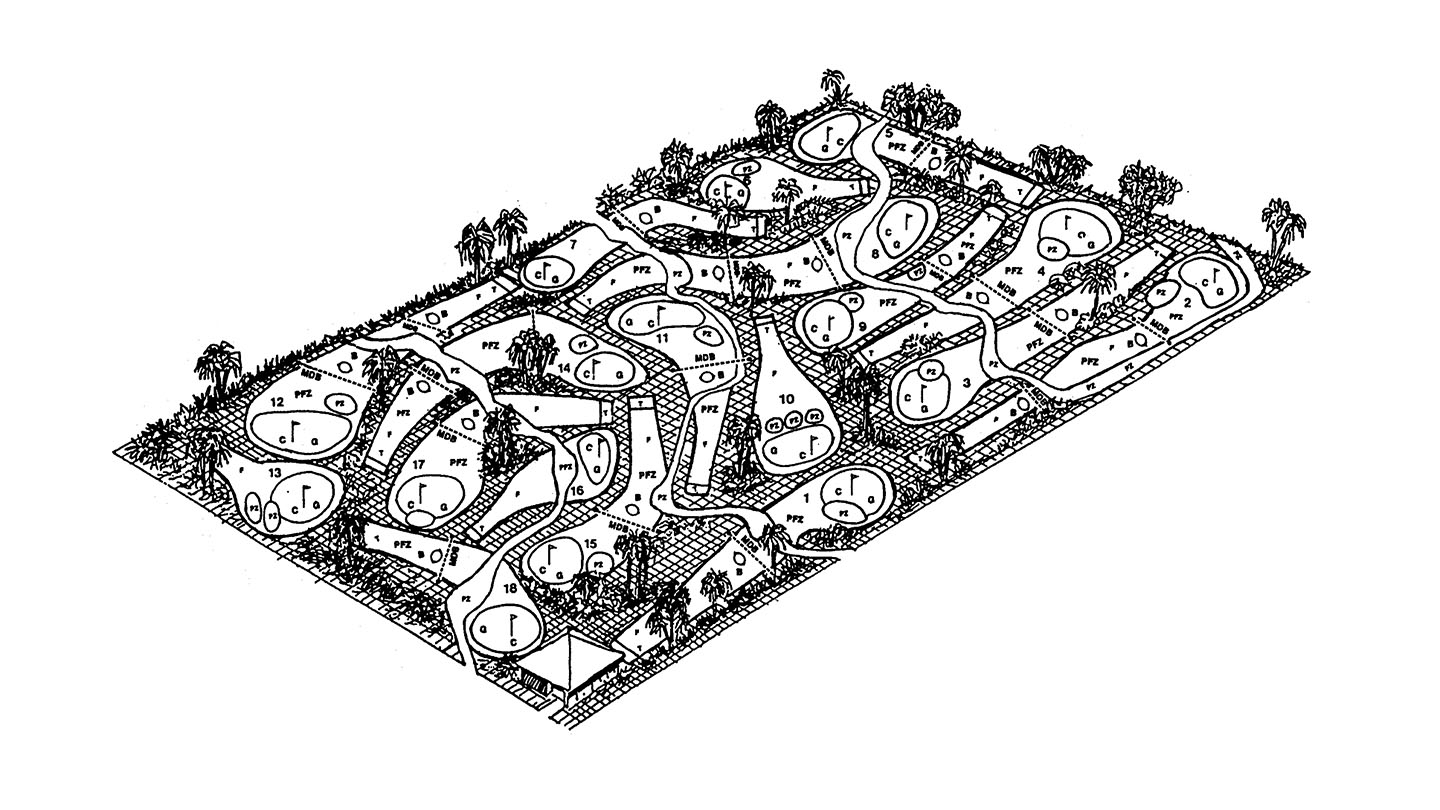

Additionally, there are patent filings for cigarette burn-proof artificial turf, and systems meant to simulate the challenges of the putting green for those who couldn’t make it to a well-manicured golf course. The use of artificial grass in stadiums and fields took off through the 1970s, following its use as a replacement for natural turf at the Astrodome in Houston.

The oscillation in scope and scale, from the micro focus of the patent for a single blade of grass, to the macro focus of the patent for an entire landscape, is itself a meaningful indicator of how chemists and inventors approached the problem of manufacturing convincingly natural landscapes through synthetic means and materials. (U.S. Patent No. 5,419,561, “Method of Playing Golf Game on Reduced Size Course,” Charles G. Webber, issued May 30th, 1995)

But artificial turf both benefited and suffered from societal and cultural trends that existed around it. AstroTurf entered the market at time when American confidence and enthusiasm for chemistry and technology were surging. In the 1960s, synthetics, plastics, and polymers promised middle-class lives of ease, security, and comfort. But artificial grass soon had to contend with a national sentiment that became far more critical of technology, chemicals, and their implications. The 1970s saw revelations over the effects of dioxin, in use by American forces in Vietnam, the burying of toxic waste at Love Canal, and industry efforts to conceal deaths associated with asbestos.

The ambition to control and perfect nature, while still capturing its richness of variety, makes for a difficult and often visually perplexing representational outcome. (U.S. Patent No. 4,850,594, “Perfect Putting Surfaces,” Peter Manzione, issued July 25th, 1989)

The Gaze of the Patent Drawing

There’s a clear theme that emerges in these collections of patent filings, claims, and drawings: the greater and greater fidelity with which artificial turf attempts to depict real grass. The inventors’ engineering efforts seem squarely focused on reproducing, to an almost reverential extent, every nuance and peculiarity of natural flora.

The earliest patents describe the basic process behind manufacturing artificial turf: Small pellets of nylon synthetic polymer, along with coloring pigments (usually shades of green and yellow) and stabilizing additives are heated and extruded into thin, blade-like strands, or ribbons. These long strands are then tufted and stitched through a thick backing, generally rubber or latex, and sliced to create the impression of individual blades. The backing is then coated with adhesive and punctured for permeability.

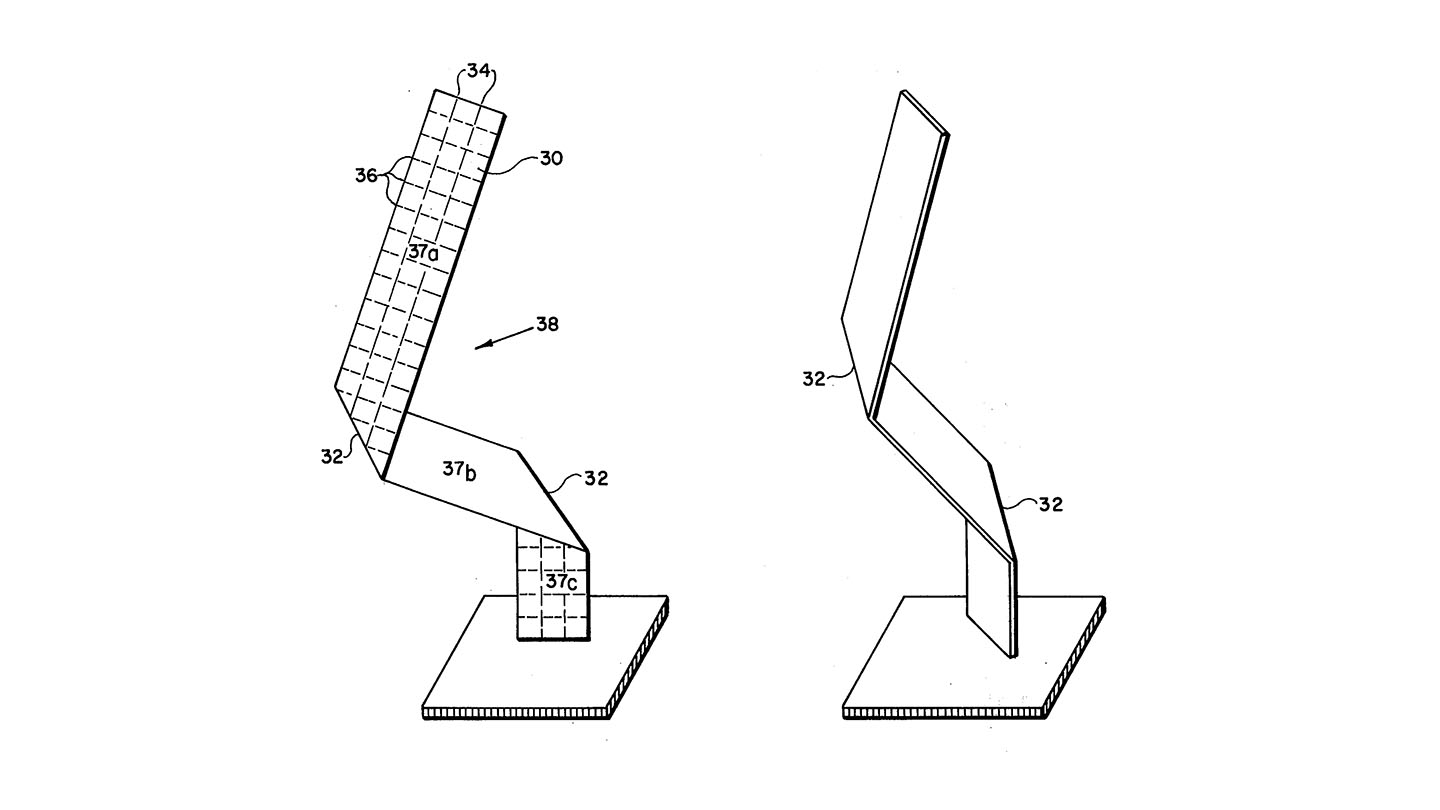

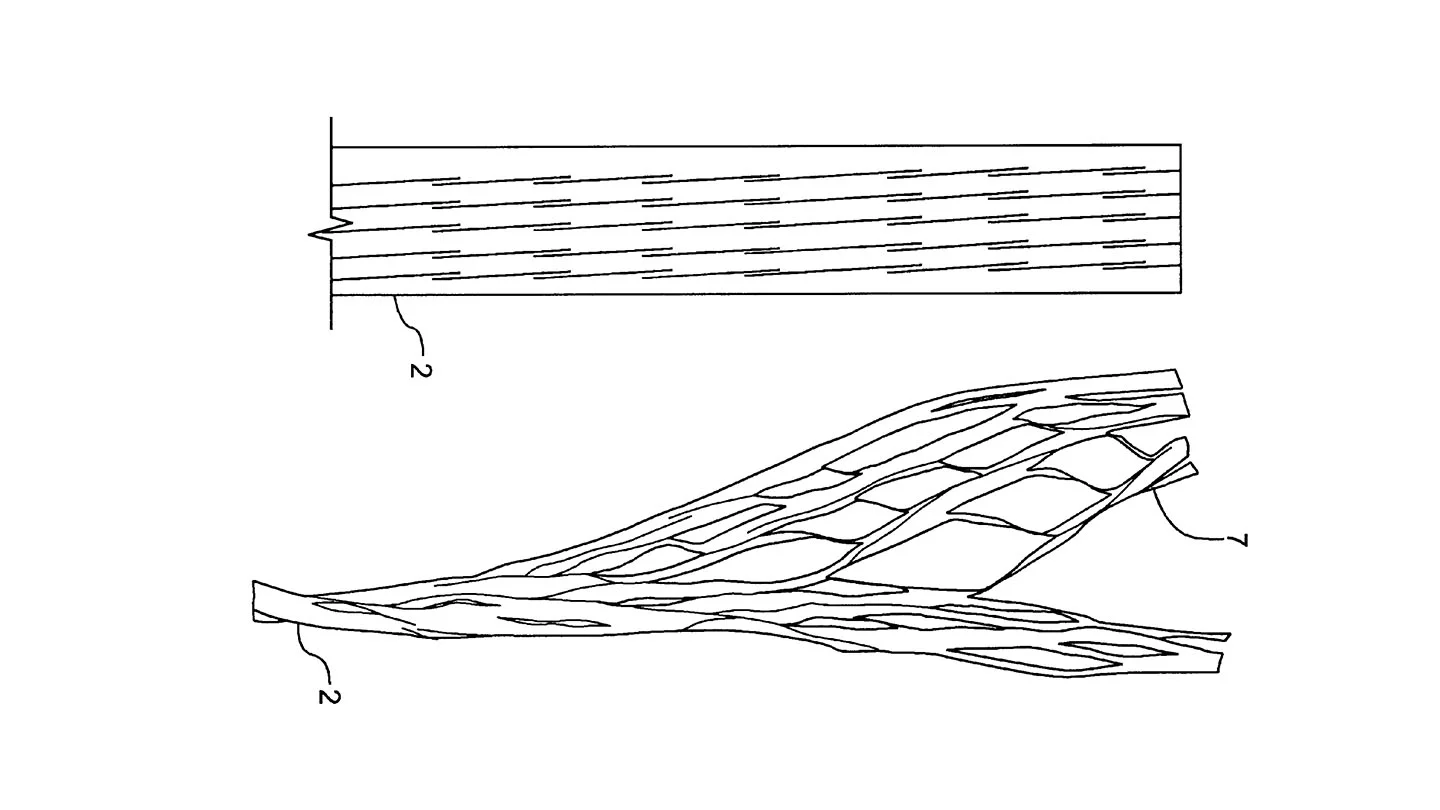

Drawings for the methods and apparatuses for tufting, or otherwise making blades of synthetic grass appear less uniform, and therefore more natural, seem to dwell obsessively on the characteristics of individual blades. Here, a blade of grass is diagrammed and depicted as one might for a work of sculpture on a pedestal. (U.S. Patent No. 4,061,804, “Non-Directional Rectangular Filaments and Products,” Walter Graham McCulloch, issued December 6th, 1977)

Over the years, technological advances centered on perfecting the tufting and structural methods behind the look of the strands, and making synthetics and weavings more durable and resistant to ultraviolet degradation.

AstroTurf and American Landscapes

But synthetic turf does more than simply reveal a discomfort with aspects of our environment that we perceive as fake, false, or artificial. It also exposes some disquieting relationships in how we think about nature, wilderness, and our domestic spaces. In his book, Ecology of Fear: Los Angeles and the Imagination of Disaster, author Mike Davis writes about suburban lawns as spaces that reveal “… the clear-cut, impermeable, but essentially imaginary boundary between the human and the wild.” Our homes provide us with a reassurance of boundaries, shelter, and safety. The grass that so characteristically surrounds the typical suburban home is a symbolic gradient between the wilderness of the outdoors and the comfort of the indoors. The lawn serves to soften the metaphorical edges of the walls and roofs around us, and to make this stark divide between indoor and outdoor less visually jarring. Perhaps, when applied to the spaces around our homes, synthetic turf is a way to make the natural world more stable and predictable—to bring the wilderness under our control.

A cross section of a spiraled blade of artificial grass, among the more recent advances in aesthetic fidelity to natural grass. The text of many patent filings reveals an alarmingly deadpan preoccupation with the idea of not only mimicking natural phenomena, but improving on them through engineering. (U.S. Patent No. 5,601,886, “Artificial Turf,” Yoshio Ishikawa & Hiroaki Fukumoto, issued February 11th, 1997)

The occasional imposition of an undesirable aspect of the wilderness, say from a wandering coyote or prowling cougar, disrupts the yard as a buffer space, as impenetrable boundary. “The ideal suburb is adjacent to nature,” Davis continues, “but never directly implicated in it.” In this case, then, we might say that the artificial landscape could be seen as a more forceful assertion of the uncrossable divide between indoors and outdoors, development and wilderness, or civilization and nature.

Important to consider, as well, is how these unnaturally bright green swaths fundamentally change the ways in which we interact with the landscapes around us. Home ownership is a central component of the ethos of the American Dream. So much of our cultural meaning and identity, therefore, is wrapped-up in the imagery of the single family home, residential neighborhoods, and the span of yards that punctuate them. Add to that the cultural values of self-sufficiency, independence, and do-it-yourself assertiveness, which for many Americans, have historically been expressed through the care and attention that we put into working on our homes and gardens.

The effort that many people devote to their foliage, flowers, shrubs, and bushes, is a labor of nurturing and sustaining a collection of living organisms—the plant life that surrounds our homes. But opting for artificial turf changes much of this work into an effort to simply maintain something that was mechanically produced, not nurtured and grown. Instead of watering, edging, fertilizing, weeding, mowing, trimming, and cutting, the synthetic yard demands a type of upkeep that is less attached to the ambition to nourish and encourage natural growth, but simply to maintain a product in “like new” condition.

Rather than cultivating a living thing, the focus of work becomes maintaining as much as possible the perpetual sameness of a factory-produced artifact. Artificial lawns are installed, occasionally brushed or sprayed clean, and eventually removed to make way for a replacement covering. A typical lifespan for an artificial lawn is 25 years. In many cases, the turf may be subject to a product warranty, or to some other guarantee of satisfaction.

Turning a natural span of lush, grassy turf into an artificial consumer product reflects almost perfectly on the ambition of the very yardwork that it makes redundant. The yard, after all, is a space where wildness is tamed, brought under strict control for the appreciation of the property owner. The American lawn is a public display of control, stability, and ambition. The more fussily agonized and excruciatingly finished the detail, the more the property owner’s mastery of the landscape is asserted. And so we might imagine, is that property owner’s mastery of social and professional realms of life, as well.

And as shifting environmental patterns continue to impact the accessibility and abundance of resources—including fossil fuels, plant habitats, and freshwater reserves—it’s worth focusing more of our collective attention in consideration and discussion about what cultural artifacts and social practices are worth maintaining, radically altering, or doing away with altogether. Is a natural grass lawn worth the threat of depleted aquifers? Are facsimile yards worth the expenditure of fossil fuels? Or would we be better off fundamentally rethinking the organization and distribution of the built environments around us?

Digital design and fabrication technologies now play a greater and greater role in the production of the designed world around us. Platforms for 3D printing, scanning, and online distribution of 3D files suggest the possibility for more engagement with the general public and the designed objects that characterize our everyday lives.

The representation from manufacturing process and method to convincingly simulated outcome. (U.S. Patent No. 6,551,689 B1, “Synthetic Grass with Resilient Granular Top Surface Layer,” Jean Prevost, issued April 22nd, 2003)

It’s not difficult to imagine a day in which extruded petroleum filaments and layers of synthetic backing can be manufactured in such a way as to blur any easy distinction between fake grass and real grass. Or a world of custom printed lawns and laser-engraved blades of grass with the homeowner's monogram or family crest repeated endlessly at near-microscopic scale.

We might agonize over the idea of the lawn as no longer a space of clear distinctions and boundaries, whether between drought or flood, indoors and outdoors, or real and fake. But at least we can derive some comfort in the knowledge that the patent drawings for “Real Fake Grass” will probably look amazing.

A hard divide between concrete and synthetic turf on a sidewalk on Los Angeles Street in the Skid Row neighborhood of Downtown Los Angeles. (Photograph by Ian Besler)

With Thanks

Vinca Kruk, Meg Neal, and Alissa Walker.

A version of this essay was originally published on Gizmodo.

Besler & Sons is a Los Angeles based practice that works across multiple sites of production. They work through references to reuse things that are already in circulation—things that they find interesting—and refit them into a slightly different framework through models, mockups, media, and software. Sometimes those references are really clear in their work, sometimes they’re not. Erin Besler was born in Chicago, Illinois. She is faculty at UCLA in the Department of Architecture & Urban Design. Ian Besler was born in Chicago, Illinois. He is a media design researcher at Art Center College of Design

beslerandsons.com